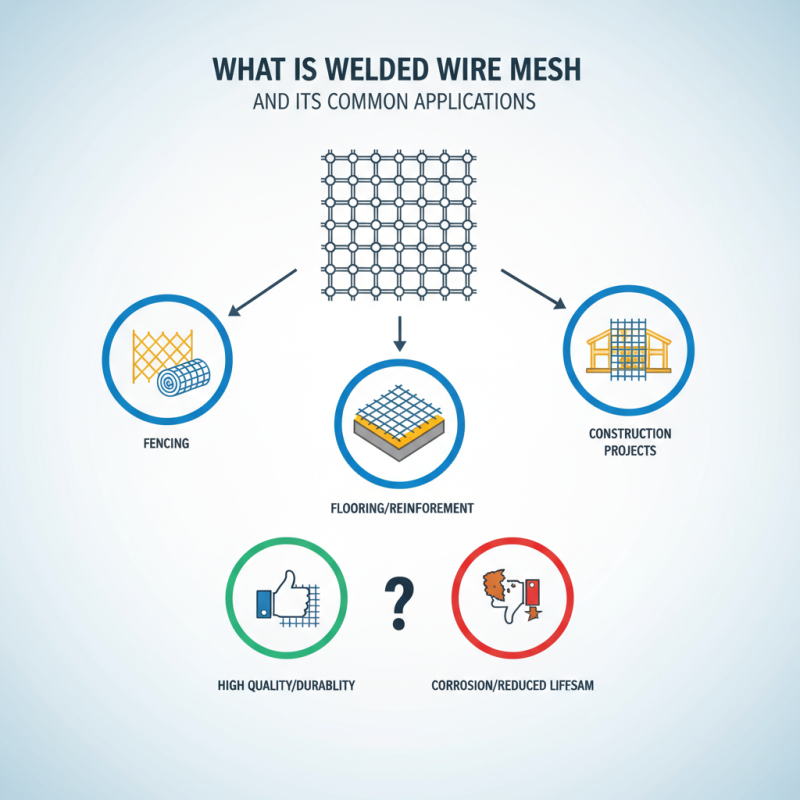

What is Welded Wire Mesh and Its Common Applications?

welded wire mesh is an essential component in various industries. It is a versatile product that provides strength and stability. As John Smith, an industry expert, once said, "Welded wire mesh forms the backbone of many construction projects." This statement highlights its importance.

This mesh is made from a series of metal wires that are welded together at intersections. The result is a grid-like structure that offers high durability. It finds common applications in fencing, flooring, and reinforcement.

However, not all welded wire mesh is created equal. The quality can vary, which impacts its effectiveness. Some products may rust over time, reducing their lifespan. Choosing the right type is crucial. By understanding its uses, one can better appreciate its role in construction and safety.

What is Welded Wire Mesh?

Welded wire mesh is a versatile material made from cross-welded wires. Typically, it consists of continuous horizontal wires that are welded to vertical wires at regular intervals. This method creates a strong structure, ideal for various applications. According to industry reports, the global welded wire mesh market was valued at approximately USD 5 billion in 2022. The demand continues to rise as construction and agricultural industries thrive.

Welded wire mesh finds use in numerous fields, from construction projects to livestock fencing. In concrete reinforcement, it works effectively to enhance structural integrity. Additionally, it serves in security applications, providing barriers that deter intruders. Many manufacturers emphasize the importance of quality in producing welded wire mesh. The spacing and diameter of the wires directly impact durability and strength.

Tips: When selecting welded wire mesh, consider the gauge and spacing. Thicker wires offer increased strength. Ideal mesh spacing depends on your specific project needs. Assess the environment where it will be used. Whether indoors or outdoors, corrosion resistance is crucial. Overlooking this can lead to premature failure.

Different Materials Used in Welded Wire Mesh Manufacturing

Welded wire mesh is commonly made from various materials. The most popular choices include steel, stainless steel, and galvanized wire. Steel offers excellent strength and is ideal for construction uses. Its durability makes it a favorite among builders. However, steel may corrode over time without proper treatment.

Stainless steel provides resistance to rust and corrosion. This quality makes it suitable for outdoor applications. It may be more expensive than other materials. Yet, many consider this investment worthwhile due to its longevity. Galvanized wire, coated in zinc, is another common choice. It combines cost-effectiveness with decent durability.

Each material has its benefits and drawbacks. Steel is strong but needs protection against rust. Stainless steel is long-lasting yet pricey. Galvanized wire is affordable but may wear out quicker in harsh conditions. Understanding these nuances is key to making the best choice for specific needs.

Common Applications of Welded Wire Mesh in Construction

Welded wire mesh is gaining traction in the construction industry. It serves various purposes due to its strength and versatility. A recent report noted that the global market for welded wire mesh is expected to reach approximately $3.6 billion by 2025. Builders increasingly prefer it for structural reinforcement and safety barriers.

One common application is in concrete slabs. Welded wire mesh enhances the tensile strength of concrete. An effective slab reduces cracking and improves durability. Additionally, it is used in road construction. The mesh supports asphalt and minimizes deformation over time. Such applications highlight its importance in modern infrastructure.

However, there are challenges to consider. Installation can be labor-intensive. Improper handling may lead to damage, affecting integrity. Moreover, some regions face issues with low-quality materials. These factors can undermine the contributions of welded wire mesh. It is essential for contractors to prioritize quality and proper installation practices.

Common Applications of Welded Wire Mesh in Construction

Benefits of Using Welded Wire Mesh in Various Industries

Welded wire mesh is a versatile construction material. It consists of steel wires arranged in a grid pattern, welded at their intersections. This design provides strength and stability, making it ideal for various applications.

Using welded wire mesh has numerous benefits in various industries. In construction, it reinforces concrete, improving durability. It helps to create strong, stable structures, reducing the risk of cracking. This safety aspect is crucial for long-term performance.

In agriculture, welded wire mesh is used for fencing and animal enclosures. It prevents animals from escaping or intruding. Additionally, it's an effective way to protect plants from pests. However, it's essential to choose the right gauge for specific needs.

**Tip:** Always consider environmental factors before choosing materials. For instance, coastal areas may require rust-resistant options.

In landscaping, welded wire mesh supports soil erosion control. It can help create strong retaining walls or garden beds. While it provides solid support, careful installation is vital to ensure effectiveness.

**Tip:** Regular inspection and maintenance can enhance longevity. Look for signs of wear or corrosion to address issues early.

What is Welded Wire Mesh and Its Common Applications?

| Dimension | Material | Application | Benefits |

|---|---|---|---|

| 1/2" x 1/2" | Galvanized Steel | Concrete Reinforcement | Increased Strength and Durability |

| 3/4" x 3/4" | Stainless Steel | Animal Enclosures | Corrosion Resistance |

| 1" x 2" | Mild Steel | Construction Fencing | Easy Installation |

| 2" x 4" | PVC Coated Wire | Garden Fencing | Aesthetically Pleasing |

| 6" x 6" | Reinforced Steel | Industrial Applications | High Load-Bearing Capacity |

Maintenance and Installation Tips for Welded Wire Mesh Products

Welded wire mesh is widely used in various construction and industrial applications. However, ensuring its longevity requires proper maintenance and installation strategies. Here are some essential tips to help you care for welded wire mesh products effectively.

When installing welded wire mesh, it’s crucial to check the ground surface. Uneven or soft ground can cause installation issues and eventual mesh failure. Always use galvanized mesh for outdoor projects. This material resists rust and corrosion. Regular inspections are necessary, especially after heavy rain or snow. Look for signs of wear or loosening.

Maintenance is key to the durability of your welded wire mesh. Regular cleaning helps prevent dirt and debris buildup. A simple rinse with water can do wonders. Additionally, consider applying a protective coating after installation. This can enhance its lifespan significantly. Over time, check for any damaged sections. Prompt repairs can save time and money in the long run.

Remember, even with proper care, issues can arise. Don’t overlook small wear signs. They could lead to bigger problems later on. Reflexivity in your approach will help maintain a safe and effective installation. Keeping these tips in mind will ensure that your welded wire mesh products serve their purpose efficiently.