2026 How to Choose Stainless Steel Wire Mesh for Your Needs?

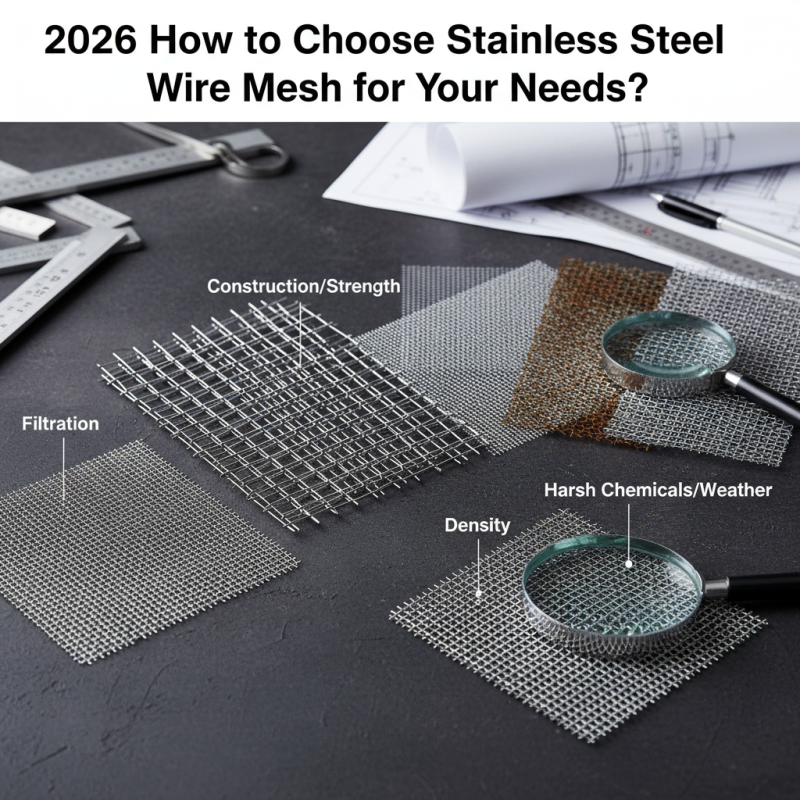

Choosing the right stainless steel wire mesh can be challenging. Many options are available, and each has unique characteristics. Stainless steel wire mesh is valued for its strength, durability, and versatility. It is used in various applications, from construction to filtration.

When selecting stainless steel wire mesh, consider your specific needs. Think about the size, wire gauge, and mesh openings. A finer mesh may be suitable for filtering, while thicker wire provides higher strength. An imperfect choice can lead to issues later, like reduced efficiency or unnecessary costs.

Reflect on how the stainless steel wire mesh will be used. Will it face harsh weather or chemicals? These factors can influence the type of stainless steel required. Moreover, it's essential to consider the mesh's density, which can impact its performance. Taking the time to assess your requirements will help ensure you find the best product for your projects.

How to Identify Your Specific Needs for Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, identifying your specific needs is crucial. Start by considering the application of the mesh. Different industries can have vastly different requirements. For instance, a food-processing facility may need mesh with a specific filtration grade. In contrast, an architectural project may prioritize aesthetic qualities. According to the latest industry reports, nearly 45% of stainless steel mesh applications are in construction and building supplies.

Next, consider the mesh specifications. The wire diameter and mesh opening size directly influence the performance. A smaller opening may provide better filtration but could reduce strength. Interestingly, 35% of users report dissatisfaction with their current mesh due to unforeseen durability issues. Does your project require flexibility or rigidity? Understanding the trade-offs here can lead to better decision-making.

Finally, assess environmental factors. Will the mesh be exposed to harsh chemicals or extreme temperatures? These conditions demand a better quality grade. Industry publications warn that neglecting these factors can lead to premature failure in 60% of cases. Your analysis should encompass the long-term performance expected from the wire mesh. Balancing various factors is key to navigating through your options effectively.

Key Factors Influencing the Selection of Stainless Steel Wire Mesh

When choosing stainless steel wire mesh, several key factors come into play. First, consider the material grade. Different grades, such as 304 and 316, offer varying degrees of corrosion resistance. A 316 grade is better for marine environments, while 304 might suffice for indoor applications. Durability matters too. Thicker wires might provide better strength, but could be harder to work with.

Next, the mesh opening size is crucial. Smaller openings can filter fine particles, while larger ones allow for better air flow. Think about your specific needs. Do you need filtration, or just structural support? This choice affects both functionality and safety. It's essential to actually measure the space you intend to use. Overlooking dimensions could lead to costly mistakes.

Lastly, consider the mesh pattern. Woven and welded meshes provide different benefits. Woven mesh offers flexibility, whereas welded mesh gives more strength. Don't rush this decision. Reflect on your can’t-miss requirements and potential compromises. Error in selection can result in frustration.

Understanding Wire Mesh Grades: A Focus on 304 and 316 Stainless Steel

When selecting stainless steel wire mesh, understanding the differences between grades is essential. Two common grades are 304 and 316 stainless steel. The 304 grade is often used due to its excellent corrosion resistance and affordability. It is suitable for a variety of applications, such as food processing and general construction. However, it may not withstand harsh environments, like those with high saline exposure.

In contrast, 316 stainless steel offers superior corrosion resistance, particularly against chlorides. This makes it ideal for marine applications and chemical processing. However, it comes at a higher price point. It’s important to consider the specific environment in which the mesh will be used. Assessing the potential for corrosion can lead to better long-term choices.

Many people overlook the value of investing in the right grade. Choosing a cheaper option may save money initially but could lead to costly repairs later. A thoughtful approach is necessary. Reflecting on your specific needs can help ensure that the right wire mesh is chosen without cutting corners.

Mesh Size and Opening: Choosing the Right Dimensions for Your Application

When choosing stainless steel wire mesh, the dimensions are critical. The mesh size and opening determine its strength and application. Different industries require specific mesh sizes for optimal performance. For example, a 100 mesh stainless steel screen has openings of 0.149mm. This fine mesh is ideal for filtering liquids or powders. Conversely, larger openings are necessary for applications like sieving larger materials.

Tips: Consider the material you are working with. Different applications may need different mesh sizes. For instance, when dealing with thicker liquids, a coarser mesh is often more effective.

Another aspect to consider is the wire diameter. A thicker wire can increase the mesh's strength but may reduce the number of openings. Reports show that a wire diameter of 0.5mm offers a balance between durability and filtration capability for many applications.

Tips: Always test different mesh sizes in real-world conditions. Gather feedback and adjust as necessary. It’s not uncommon for an initial choice to require adjustments based on performance. Evaluating both mesh size and wire diameter ensures the best results for your specific needs.

Evaluating Corrosion Resistance and Durability in Wire Mesh Selection

When selecting stainless steel wire mesh, corrosion resistance is crucial. Different stainless steel grades offer varying levels of resistance. For example, type 304 is common but may not withstand harsh environments. In coastal areas, type 316 is often preferred due to its impressive resistance to saltwater. Durability factors into the decision as well. Thicker wires usually provide better strength, leading to a longer lifespan.

Consider the environment where the mesh will be used. Will it face chemicals? Humidity? The type of exposure can impact the performance and longevity of the wire mesh. Also, remember that even high-quality stainless steel can corrode under specific conditions. Proper installation and maintenance play a significant role in its durability. Neglect can lead to premature failure. It's essential to think critically about all these factors before making a choice.

Wire mesh selection is not always straightforward. Many users overlook minor details, leading to dissatisfaction. Reviewing specific needs and environmental factors can help clarify the right choice. Not every application requires the most durable option. Sometimes, a less expensive, moderately durable mesh may suffice. It's essential to strike the right balance without compromising quality.